Operating and Maintaining Graders: Best Practices and Solutions

Date: 14/09/2022

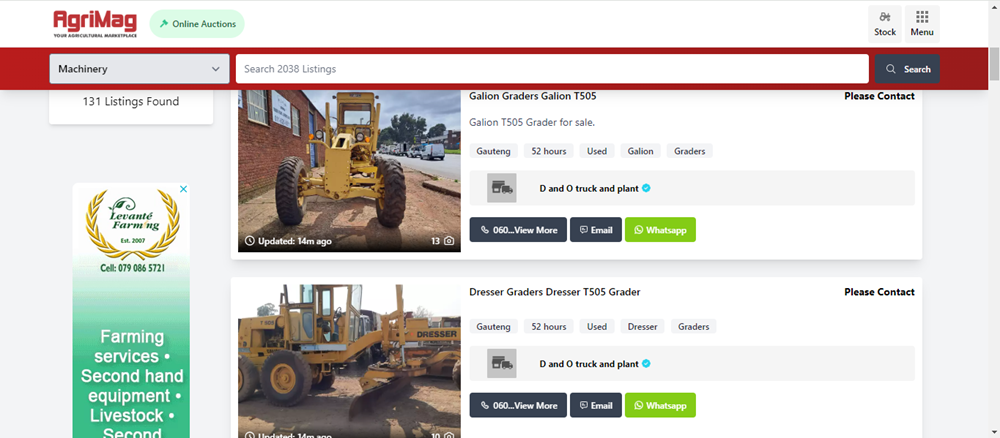

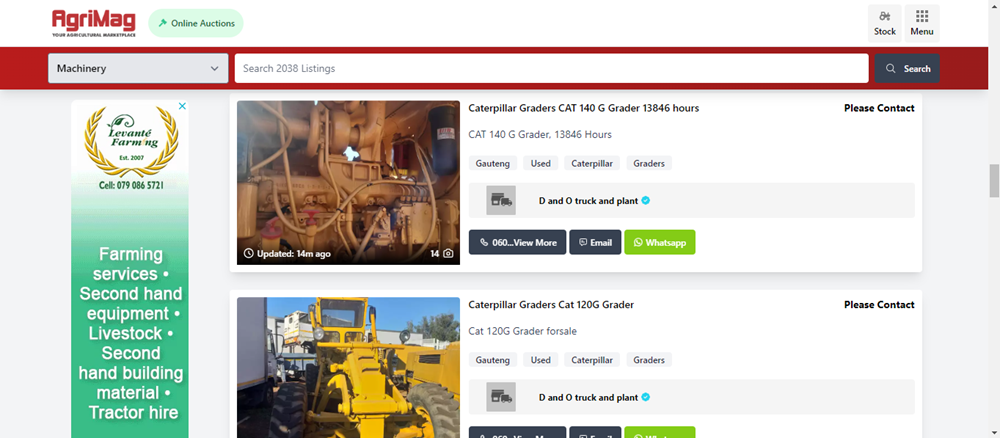

In South Africa, the construction and mining sectors heavily rely on heavy machinery such as graders for their daily operations. Efficiently operating and maintaining these graders is crucial for ensuring their longevity and optimal performance. This article explores the best practices for operating graders and addresses the common maintenance challenges, offering practical solutions specific to the South African context. Want to know more about machinery? Read blog articles on AgriMag.

Best Practices for Efficient Operation of Graders

Operating graders efficiently not only enhances productivity but also reduces wear and tear, extending the lifespan of the machinery. Here are key practices to ensure efficient operation:

1. Operator Training

Proper training is fundamental. Operators should understand the specific functions and capabilities of the grader model they are using. In South Africa, where terrain and climate can vary dramatically, operators need to be skilled in adapting their techniques accordingly.

2. Pre-Operation Checks

Before commencing any grading task, a thorough check of the grader is essential. This includes inspecting the hydraulic systems, blade alignment, and tire pressures. Such checks can prevent breakdowns that may occur due to overlooked issues.

3. Use the Right Tools for the Job

Utilising the correct attachments and tools for specific tasks can significantly enhance the grader’s efficiency. For instance, different blade types are better suited for different materials and surfaces, whether grading gravel roads or fine-tuning slopes.

4. Implement Efficient Grading Techniques

Efficient grading techniques, such as maintaining a consistent blade angle and understanding when to adjust the blade height, are crucial. These techniques reduce the amount of rework and material wastage, which is particularly important in resource-sensitive operations.

Maintenance Challenges and Solutions

Maintaining graders in South Africa can present unique challenges due to the country's diverse climate and rough terrain. Here are some of the common issues and practical solutions:

1. Dealing with Dust and Debris

South Africa’s many arid regions mean that graders often operate in dusty conditions, which can clog filters and affect engine performance. Regularly replacing or cleaning air filters and ensuring seals and housings are intact can mitigate these issues.

2. Handling Harsh Environmental Conditions

Extreme temperatures and varying weather conditions can impact the hydraulic systems and batteries. Using high-quality, temperature-resistant fluids and ensuring that batteries are regularly checked and maintained are vital steps in overcoming these challenges.

3. Preventive Maintenance

Implementing a robust preventive maintenance schedule is crucial. This includes regular oil changes, hydraulic system checks, and immediate repairs of any minor issues before they escalate into major problems.

4. Availability of Spare Parts

One of the biggest hurdles in maintaining graders is the availability of genuine spare parts. Establishing relationships with reliable suppliers and keeping a stock of essential parts can greatly reduce downtime.

5. Technical Support and Service

Access to expert technical support is essential, especially for complex issues. Partnering with a reputable service provider who understands the specifics of graders used in the South African market can provide peace of mind and reduce service delays.

Efficiently operating and maintaining graders in South Africa requires a combination of skilled operation, routine maintenance, and the ability to adapt to local conditions. By adhering to best practices and addressing common maintenance challenges, operators can ensure their graders perform optimally and have an extended service life. Embracing these strategies will significantly benefit the productivity and efficiency of any project involving these pivotal machines. Do you wish to learn more about machinery? Browse AgriMag's blog posts.

Categories:

Common category

Category Search:

Latest articles:

What to Look for When Buying a Skidsteer Loader for Farming

Why Planning Early for the Planting Season Pays Off

Why Winter Feed Management is Crucial for Livestock Health